Services

Co-design

Co-design service for tailored solutions

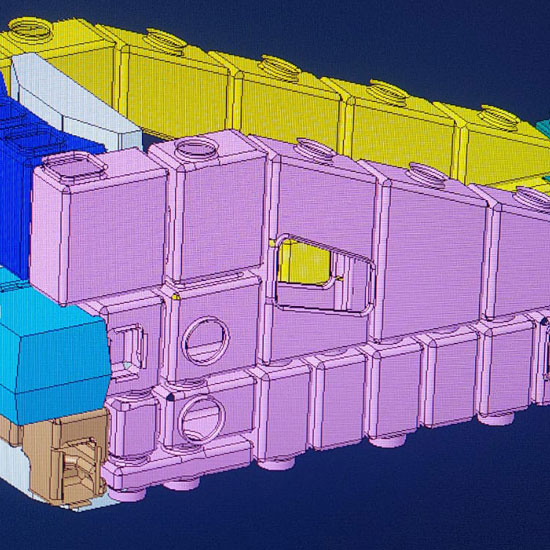

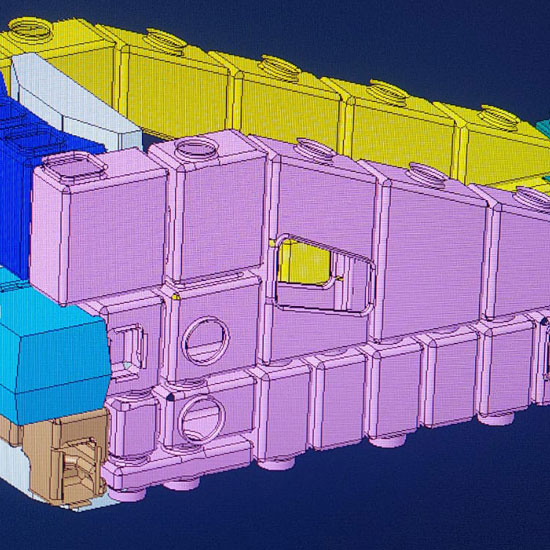

Model construction

Wood, polystyrene and resin model construction

Construction of patterns in wood, polystyrene, and resin through 3D design: in Fonderia Marini the attention of the details and precision are essential. Each project begins with an accurate 3D modeling, allowing the design to be visualized and performed before production. We use advanced techniques to make wooden equipments , ideal for high-quality metal castings as well as polystyrene and resin one suitable for more complex or experimental productions. This integrated approach ensures customized solutions that perfectly satisfy our customers’ needs with reliable and precise results.

Storage

Model storage warehouse: security and organization

Model storage area in a specific 1.200 sqm warehouse, with smoke detection and fire prevention system: in Fonderia Marini, safety and organization are our top priorities. Our warehouse, spacious and well-structured, is designed for the safe storage of wooden, polystyrene, and resin models, with a controlled environment that preserves the integrity of the materials. An advanced smoke detection system and a fire prevention system ensure continuous protection from potential risks. Thanks to an optimal layout of the spaces, the models are easily accessible, ensuring efficient and organized management for each project.

Heat treatment

Heat treatments for stabilization and ferritization

Internal stabilization and ferritization heat treatment with customized heating ramps: at Fonderia Marini, we offer specialized heat treatments to ensure the highest quality of our castings. Stabilization helps reduce internal stresses in materials, ensuring greater durability and dimensional accuracy. Ferritization, on the other hand, improves the crystalline structure of the metal, optimizing its mechanical properties. Thanks to the use of customized heating ramps, we can tailor each process to the specific needs of the client and the project, achieving optimal results. All of this takes place internally, ensuring reduced lead times and complete quality control throughout the entire production cycle.

Transport

Transport free to the customer with the internal fleet of Fonderia Marini

We offer a full and reliable logistics service with our own trucks: at Fonderia Marini, we ensure that the transport service is efficient and tailored to meet the needs of our clients. Thanks to our fleet of trucks, we can ensure the timely delivery of products directly to the customer. This allows us to efficiently and safely manage the transportation of even large components, maintaining control over delivery times and the condition of the materials. The “franco cliente” service ensures that each product arrives at its destination in perfect condition, ready to be used or further processed according to specific requirements.

Mechanical machining

External mechanical machining with qualified suppliers

Possibility of mechanical processing on produced castings: at Fonderia Marini, we offer advanced mechanical processing services through a network of qualified suppliers. After the production of castings, we can carry out additional mechanical processing to refine and adapt the components to the customer’s exact specifications. We collaborate with expert partners who ensure high standards of precision and quality. This integrated approach allows us to manage every phase of the project efficiently, ensuring final results that fully meet technical and performance requirements. Our ability to coordinate these external services adds value and versatility to our production process.